The Efficiency of an Optical Fibre Diameter Analyser in Reducing Manufacturing Errors

Just How an Optical Fibre Diameter Analyser Enhances High Quality Control in Fibre Manufacturing

The integration of an Optical Fibre Diameter Analyser right into Fibre production processes represents a substantial innovation in high quality control methodologies. By providing real-time, specific measurements of Fibre diameters, this innovation resolves the crucial requirement for uniformity in production standards.

Value of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is essential in the field of optical Fibre technology, as it straight affects the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and general transmission efficiency. Precision in gauging Fibre Diameter guarantees that the optical homes are maintained within defined resistances, which is crucial for ideal signal integrity.

Variations in Fibre Diameter can lead to raised losses as a result of scattering and modal dispersion, influencing the top quality of information transmission. In high-speed communication systems, such discrepancies can cause considerable deterioration of signal quality, bring about data errors and decreased performance. Regular Fibre Diameter is necessary for compatibility with connectors and splicing modern technologies, which are important parts of Fibre optic networks.

Quality assurance processes in Fibre production greatly rely on exact Diameter dimensions to guarantee conformity with industry requirements. By implementing durable dimension strategies, suppliers can enhance item reliability, lessen waste, and improve general system efficiency. Thus, the value of Fibre Diameter measurement can not be overemphasized, as it works as a foundation in the advancement of optical Fibre innovation and its applications in modern-day communication networks.

Exactly How the Analyser Functions

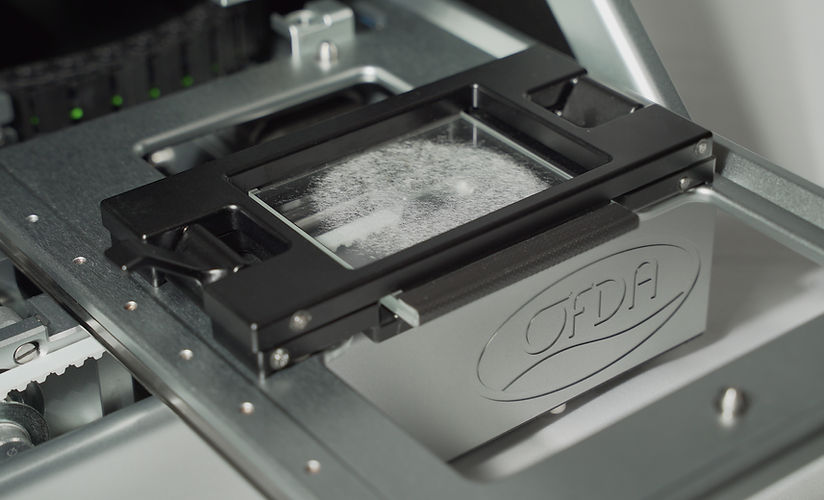

The effective measurement of Fibre Diameter relies on sophisticated logical techniques that guarantee accuracy and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser modern technology and progressed image processing algorithms to precisely analyze the Diameter of fibres as they are created

At first, a laser light beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this darkness making use of high-resolution cameras positioned tactically along the assembly line. The recorded photos are after that refined in real-time to determine the Fibre's Diameter with extraordinary precision.

The system makes use of innovative formulas that account for various elements, including variations in light intensity and environmental conditions, to enhance measurement dependability. It can find minute adjustments in Diameter, such as changes that could happen throughout the manufacturing process.

Moreover, the analyser can taking care of numerous fibers all at once, boosting throughput without jeopardizing accuracy. By giving rapid comments on the Diameter, the Optical Fibre Diameter Analyser plays an essential role in maintaining rigorous quality assurance requirements, ensuring that the end product meets sector specs and customer needs.

Advantages of Real-Time Surveillance

While conventional methods of checking Fibre Diameter typically involve taxing post-production checks, real-time monitoring dramatically improves the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive technique allows makers to identify inconsistencies in Fibre Diameter as they happen, rather than waiting till manufacturing is complete to examine quality

By constantly measuring the Diameter throughout production, producers can ensure that the fibres fulfill stringent specs, leading to decreased irregularity and improved consistency. Real-time surveillance also makes it possible for immediate restorative activities to be taken, minimizing waste and stopping malfunctioning fibres from going into the supply chain.

Moreover, this modern technology helps with improved information collection and analysis, supplying understandings into production patterns and prospective locations for renovation. Such data-driven decision-making empowers producers to enhance procedures and maintain high standards of quality assurance.

On top of that, real-time monitoring fosters a culture of constant enhancement within the manufacturing atmosphere. Staff members are extra engaged when they can see the effect of their work in real-time, causing enhanced liability and a dedication to quality. On the whole, the execution of real-time surveillance systems in optical Fibre production equates to premium item top quality and boosted client contentment.

Effect On Manufacturing Effectiveness

Carrying out optical Fibre Diameter analysers dramatically boosts production efficiency by simplifying the production procedure. These gadgets assist in constant tracking of Fibre Diameter, enabling producers to discover variances in real-time. By determining inconsistencies promptly, manufacturing lines can be changed rapidly, minimizing downtime and reducing the chance of creating malfunctioning items.

Additionally, the integration of these analysers right into the production operations allows better source allowance. With accurate Diameter measurements, operators can maximize material use, making sure that resources are not lost on flawed fibers. This precision additionally contributes to much less remodel and ditch, ultimately decreasing production prices.

The automation provided by optical Fibre Diameter analysers minimizes dependence on hands-on assessments, which are frequently taxing and prone to human mistake. Consequently, staff members can focus on more critical tasks, boosting general performance.

Furthermore, the information created from these analysers can inform process renovations and facilitate much better decision-making. By assessing trends in Fibre Diameter variations, makers can apply positive measures to improve manufacturing strategies and maintain constant high quality. In recap, optical Fibre Diameter analysers play an important function in boosting manufacturing efficiency, causing greater quality output and enhanced profitability.

Study and Success Stories

Throughout various sectors, study highlight the transformative impact of optical Fibre Diameter analysers on manufacturing processes. One popular example is a leading telecommunications business that dealt with difficulties with irregular Fibre diameters, resulting in enhanced being rejected rates. By integrating an optical Fibre Diameter analyser, the company achieved real-time monitoring of Fibre measurements, causing a 30% decrease in flaws and substantial expense financial savings.

Additionally, a study organization concentrating on sophisticated products utilized optical Fibre Diameter analysers to fine-tune their experimental processes. The analyser's capacity to supply detailed understandings right into Fibre consistency enabled the growth of cutting-edge materials with enhanced performance attributes.

These success tales underscore the crucial role of optical Fibre Diameter analysers in enhancing high quality control, improving production performance, and driving innovation across varied industries.

Final Thought

In verdict, the Optical Fibre Diameter Analyser plays an essential duty in boosting high quality control within Fibre production. As demonstrated with different situation studies, the analyser shows vital for achieving exceptional product quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for rigid quality control, making sure that the produced fibers fulfilled exacting market criteria.In final thought, the Optical Fibre Diameter Analyser plays a critical duty in improving top quality control within Fibre production.